Our Processing

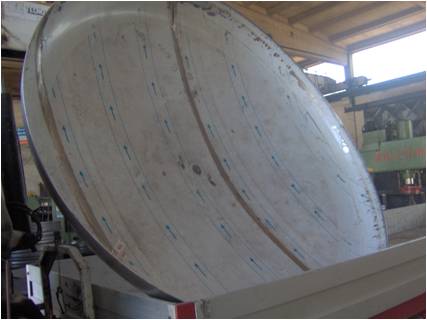

Dome base with internal mirror polish with ra < 0,1 μm

Dome base with internal mirror polish with ra < 0,1 μm

Satin Interior with grain and roughness according to needs

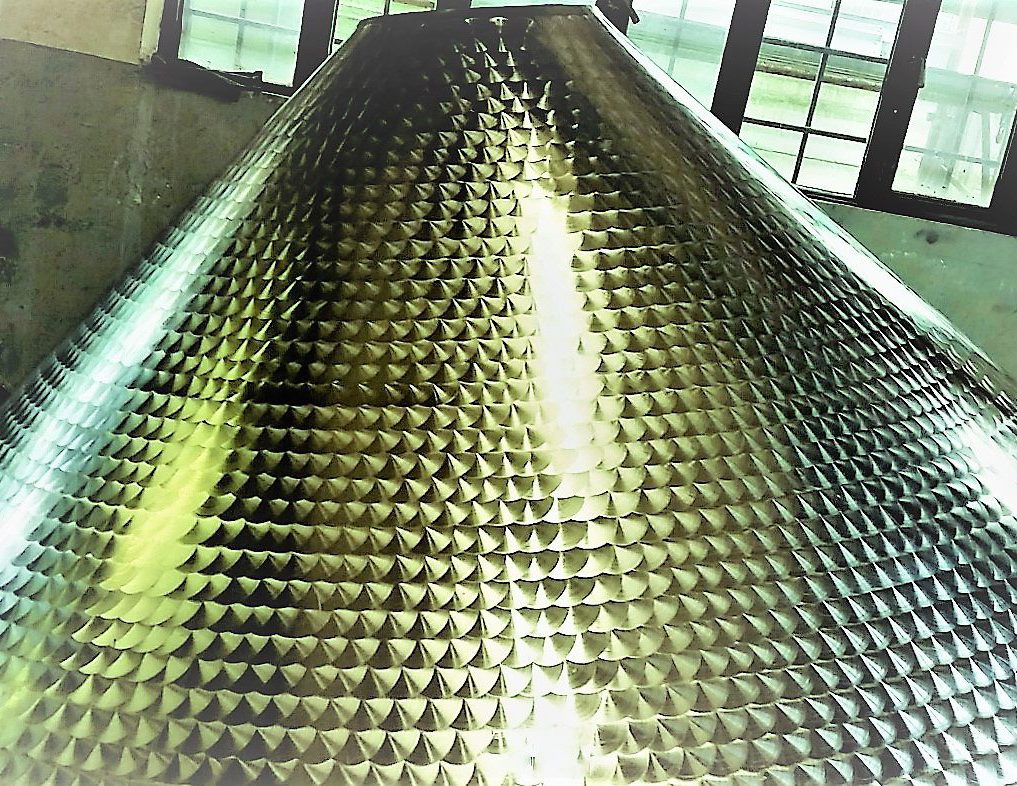

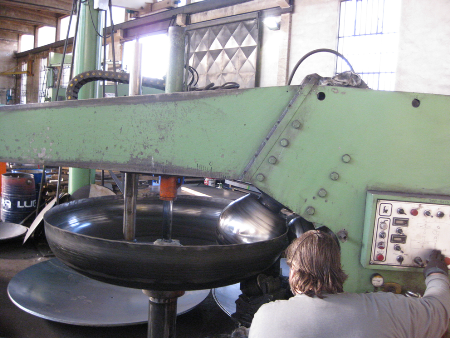

Flowered cone after forming

Rounded bottom with x-ray and external satin finish after formation

Domed bottom with holes or slots made after forming with 3D cuts

Bench welding machine with double welding process submerged arc / pulsed arc with cameras for the control of welding process

The welding processes are certified according to the uni en 1418: 1999 regulations issued by: Rina

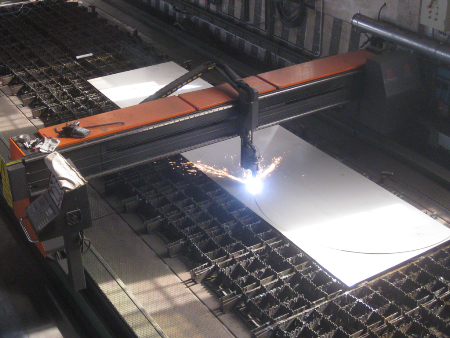

Plasma bench at c.N. Cr electronic 3000x12000x30mm.

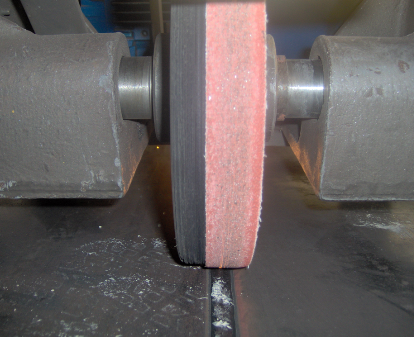

Shears with circular saw blades and mechanical cold cutting d.Max 4000x10mm.

The grinding of the welding seam is always carried out in such a way that it does not undergo or cause incisions and cracks during processing

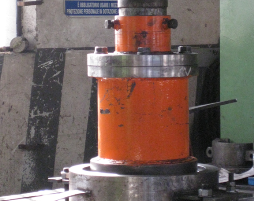

400 ton press for molding bases and special processes

Automatic 200 ton press

400 ton Press with manipulator and automatic processing cycle

Edge banding machine sp. 10 mm. D. Max. 4000

Hydraulic beading machine with possibility to bead bottoms even without center hole, sp 5 / 6mm max. of the bottom.

Edge banding machine sp. 13 mm d. Max. 3000

Hydraulic beading machine with possibility to bead bottoms also without centering hole sp 5/6 mm max. of the bottom.

Edge banding machine sp. 25/30 mm d. Max 6000

Hydraulic beading machine with possibility to bead bottoms even without holes by means of pressure anchoring.

Automatic plasma, air, nitrogen trimming.

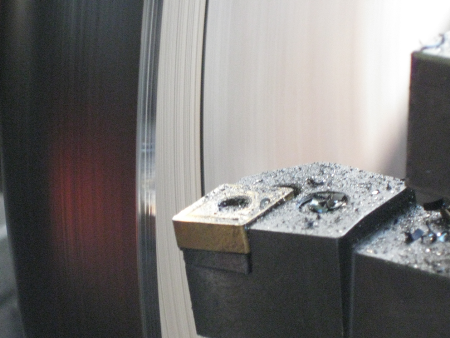

On request, trimming of pads by by lathe.

Control of the bottom in the final phase of work of the circumference.

Height and radii

Thickness control

Penetrating liquid control

X-ray controls with punching of factory number and radiogram position

the flowering of the bottom takes place after all the working of the base, thus obtaining a better finish and the absence of scratches of the flowering and the welding seam.

Formation and composition of even large hemispheres

Bottoms processed with cutting laser before forming.

Hemispherical bases in titanium steel with radiographic welds

Steel bases with 2b finishes and protection kept intact for complete duration of the work.

C.F.S. Organizes transport of special loads, throughout Italy, with certified vehicles.

d. 3500 stainless steel bases with welded stands used as a stable structure for maritime transport.

d. 4000 bases with perforated plates resting on the trestles

Bottoms and plates for filters cut in half for transport in containers.

Processing in C.F.S. is always meticulously treated by highly qualified personnel.